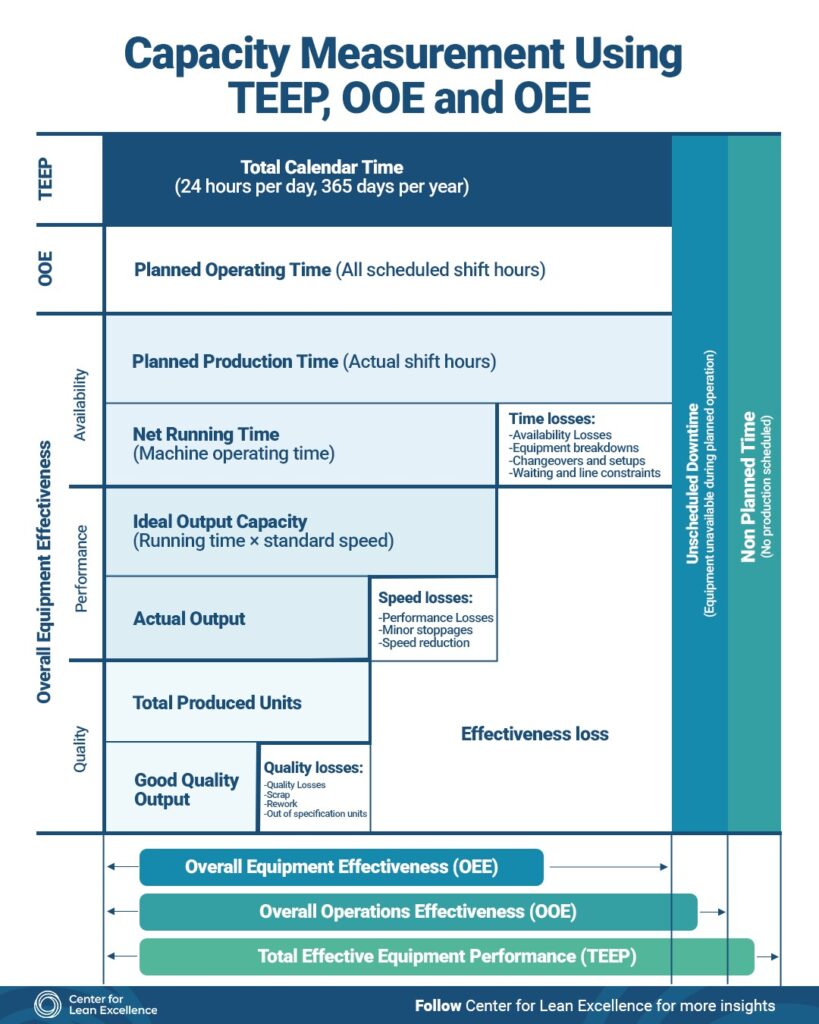

Capacity Measurement in Lean Manufacturing: How TEEP, OOE and OEE Expose the Real Performance of Your Factory

How TEEP, OOE and OEE Expose the Real Performance of Your Factory? In Lean manufacturing, capacity is often misunderstood. Many factories believe they are running at full capacity, yet they continue to struggle with missed deliveries, excess overtime, and constant production firefighting. The root cause is rarely a lack of machines or manpower; it is […]